What Do You Clean A Snaplock Floor With

Guide to Installing Laminate Floor

A snap-together fastening arrangement simplifies laminate floor laying. No gum, no nails. You can do information technology in a weekend.

![]() Time

Time

Multiple Days

![]() Complexity

Complexity

Beginner

![]() Cost

Cost

$501-1000

Introduction

Learn how to lay laminate flooring with snap-together wood. Information technology's so easy to install that you can lay a beautiful, all the same durable hardwood flooring in a weekend—no messy gum and no heavy nailing. It's prefinished likewise, so no dusty sanding and painstaking finish piece of work. In this article we'll show yous how to prepare your floor and and so lay the boards. It's the perfect project for the novice who has some simple carpentry skills.

Tools Required

Materials Required

- 4-mil plastic

- 4d terminate nails

- Construction adhesive

- Duct tape

- Floor pad record

- Flooring pad

- Masking record

- Snap-together wood floor

- Transition pieces

Buying advice and the tools y'all need for laminate floor installation

Floor board interlocking system

Snap-together floors have especially milled tongues and grooves that lock together tightly when joined when installing laminate flooring. The flooring we're using for installing laminate flooring is like to snap-together plastic laminate floors except that it has a surface layer of existent wood. The v/16-in. thick snap flooring has particularly shaped tongues and grooves that interlock to class a strong tight joint without mucilage or nails. Once the click lock laminate flooring is assembled, the entire floor "floats" in one large sheet. You leave a small-scale expansion space all around the edges so the floor can expand and contract with humidity changes.

The toll of wood veneer floors (often chosen engineered wood floors) varies, depending on the species and thickness of the top wood layer. Most home centers sell a few types of snap-together floors only you lot'll detect a better selection and expert advice at your local flooring retailer. You can also buy snap flooring online to outset a how to install laminate floors project.

Before you go shopping, describe a sketch of your room with dimensions. Make note of transitions to other types of flooring and other features similar stair landings and exterior doors. Ask your salesperson for help choosing the right transition moldings for these areas. You'll demand a few special tools in addition to basic mitt tools similar a tape measure, square and utility knife to know how to install wood floor. Nosotros purchased a laminate floor installation kit from the manufacturer that included plastic shims, a tapping block and a last-board puller, just if you're handy you could fabricate these tools. A pull saw works great to undercut doorjambs and casing (Photo 3). It's difficult to become close plenty to the floor with a standard handsaw.

Yous'll also need a round saw and a jigsaw to cut the flooring, and a miter box to cut the shoe molding. A table saw and power miter saw would make your how to install laminate floors task easier only aren't necessary. Here, we'll bear witness y'all how to install laminate floor:

Project footstep-by-stride (xiv)

Step 1

Laying laminate forest flooring: Prep the room for laying laminate flooring

Use plastic to test for moisture in concrete

You lot don't want to practise a laminate flooring installation over a damp subfloor. Test for excess moisture in concrete floors by sealing the edges of a 3-ft. square of plastic sheeting to the flooring with duct record. Look 24 hours earlier you peel dorsum the plastic to check for moisture. Water droplets on the plastic or darkened concrete point a possible problem with backlog wet. Ask your flooring supplier for advice before beginning a how to install laminated flooring job.

How Joists Work

Step 2

Check for low spots in the floor, and then fill them in.

Check for low spots in the flooring with an viii-ft. straightedge and mark their perimeter with a pencil. Fill depressions less than 1/four in. deep with layers of building newspaper. Fill deeper depressions with a hardening type flooring filler bachelor from flooring stores.

Luxury Vinyl Tile Installation

Step 3

Use a pull saw to cutting the doorjambs and casings

Undercut doorjambs and casings (door moldings) to brand space for the floor to slip underneath. Guide the saw with a scrap of laminate flooring stacked on a piece of underlayment.

Install Prefinished Wood Flooring

Footstep 4

Terminate cutting the jamb and casing

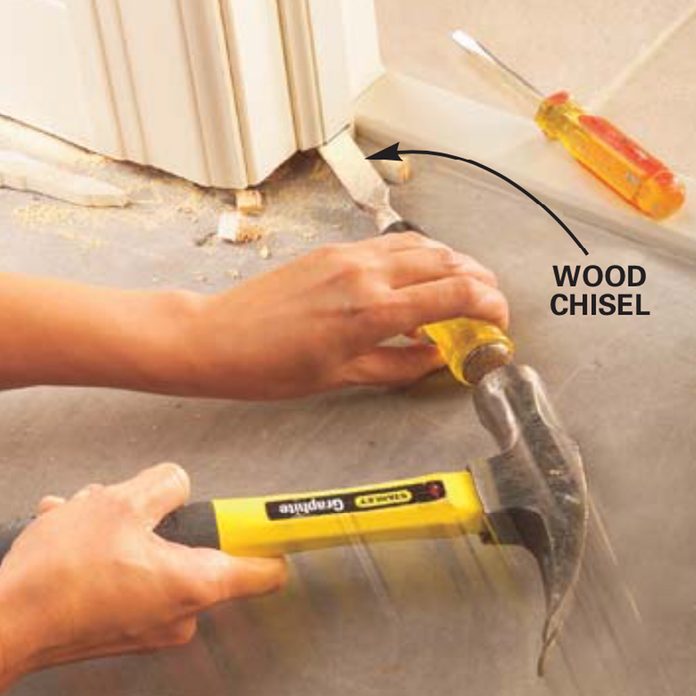

Intermission and pry out the cutoff chunks of jamb and casing with a screwdriver. Utilize a sharp chisel or utility knife to complete the cut in areas the saw couldn't reach. Brand certain your floor is dry. Don't lay this type of flooring over damp concrete or damp crawlspaces. Check all physical for excess wet. As a starting betoken, utilise the plastic mat test shown in Photograph i. Even though some manufacturers allow it, professional installers we spoke to advised against installing floating floors in kitchens, total or three-quarter baths, or entryways, all areas where they might exist subjected to standing h2o.

Then prepare your room for the new laminate flooring installation. You have to make sure the existing floor is smooth and flat before installing a floating flooring overtop. Clear the erstwhile floor, then smooth it by scraping off lumps and sweeping it. If y'all have wood floors, now's the time to ready squeaks and tighten loose boards by screwing them to the joists with deck screws. Cheque the floor with an 8-ft. straightedge and mark high spots and depressions. Sand or grind downwards ridges and make full depression spots (Photo 2). Most manufacturers recommend no more than ane/8-in. variation in flatness over an 8-ft. length.

Allowing the floor to expand and contract freely is critical. Get out at least a 3/eight-in. expansion space along the edges. Yous tin can hibernate the gap nether the baseboards or leave the baseboards in identify and cover the gap with base shoe molding or quarter round as we did. Cover the expansion space at openings or transitions to other types of flooring with special transition moldings (Photograph 13). Purchase these from the dealer.

Finally, saw off the bottoms of doorjambs and trim to let for the floor to slide underneath (Photo 3). Leaving an expansion gap at outside doors presents a unique challenge. In older houses, y'all could advisedly remove the threshold and notch it to allow the flooring to slide underneath. For virtually newer outside doors, you tin barrel a square-nosed transition piece against the threshold.

How to Install Luxury Vinyl Plank Flooring

Step 5

Follow these unproblematic how to install hardwood floor techniques

Install the underlayment and the offset row of flooring

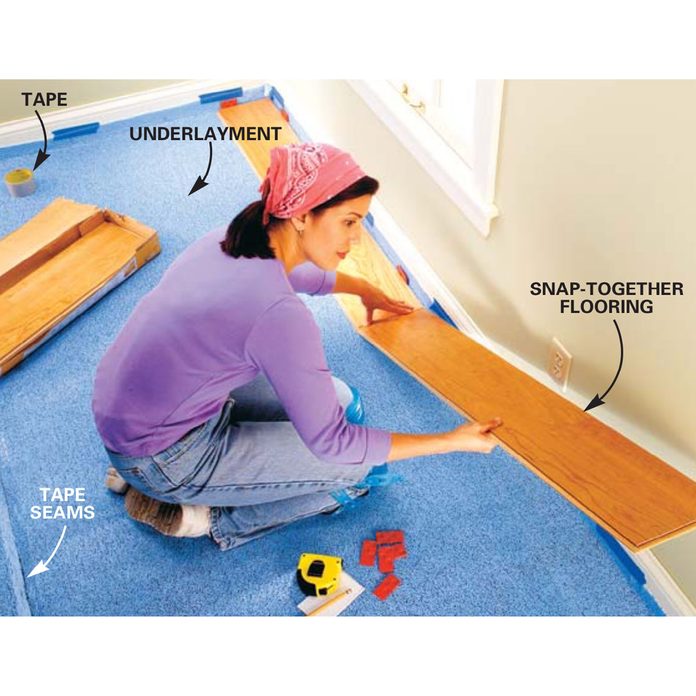

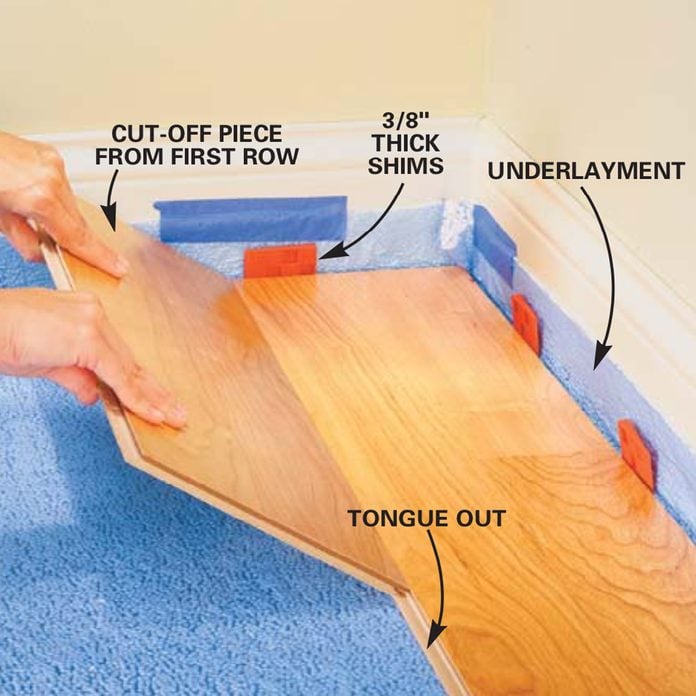

Unroll the underlayment and lap it upward the baseboards or walls 2 in. Temporarily secure the edges with masking tape. Butt the sheets together and seal the seams with the tape recommended past the manufacturer. Cut the kickoff row of boards narrower if necessary to ensure that the terminal row of floor will be at least 2 in. broad. So get-go the installation by locking the ends of the first row of flooring together. Measure and cut the terminal piece to fit, allowing the three/8-in. expansion space.

How to Install a Sheet Vinyl Floor

Step 6

Use a leftover piece to start the second row

First the second row with the leftover cutoff piece from the first row, making sure the end joints are start at to the lowest degree 12 in. from the terminate joints in the first row. With the board held at about a 45-degree angle, engage the tongue in the groove. Push in while you rotate the starter piece down toward the floor. The click indicates the pieces have locked together. The joint between boards should draw tight.

three Types of Electric Heated Floors

Footstep vii

Tap the flooring pieces tightly together

Leave a 1/four-in. infinite between the next full slice of flooring and the previous piece. Snap this slice into the first row. Snap a scrap of flooring across the ends being joined to hold them in alignment while you tap them together. Place the tapping block against the end of the floor piece and tap it with a hammer to close the gap.

Tapping block detail

A tapping block is one of the special tools in the installation kit and will aid you when you learn how to put down laminate flooring.

How to Install Pine Floors

Stride viii

Pull the terminal piece in a row tight

Close a gap at the end of the row past hooking the concluding-board puller tool over the end of the plank and tapping it with a hammer to pull the stop joints together. Floating floors must be installed over a sparse cushioning pad called underlayment (Photo 5). Underlayment is usually sold in rolls.

Ask your floor dealer to suggest the all-time i for your state of affairs. Some types combine a vapor barrier and padding. Install this type over physical or other floors where wet might be a problem. Others reduce sound transmission. Take extra care when installing underlayment that includes a vapor barrier. Lap the edges up the wall and advisedly seal all the seams every bit recommended by the manufacturer. Keep a roll of tape handy to patch accidental rips and tears as you install the floor.

You may have to cut your offset row of flooring narrower to brand sure the last row is at least two in. wide. To figure this, measure across the room and split up by the width of the exposed face on the flooring. The number remaining is the width of the last row. If the remainder is less than 2, cut the showtime row narrower to make this last row wider. After the first few rows, installation is a snap. Simply follow the guidelines in Photos vi - 8.

How to Refinish Hardwood Floors

Pace nine

Special techniques for corners and transitions

Prep flooring to fit around doorjambs

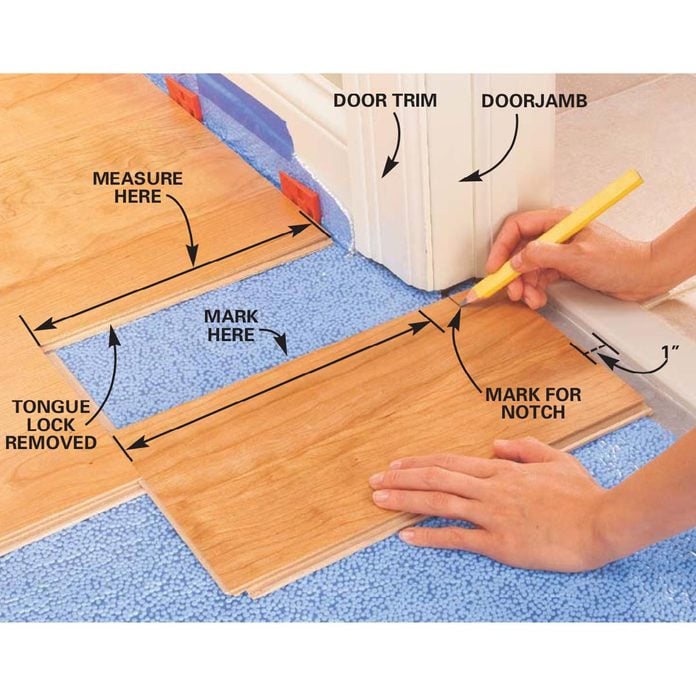

Plan ahead when you become near a doorjamb. Usually you have to slide the next piece of flooring under the jamb rather than tilt and snap it into identify. To accomplish this, you must slice off the locking section of the tongue from the preceding row with a sharp utility knife before installing it.

How to Clean Hardwood Floors with Natural Products

Step x

Mark a plank to fit a doorjamb

Cut the plank to be notched to length, allowing a 1-in. space for the future transition piece. Align the end with the end of the last plank laid and mark iii/viii in. inside the jamb to make sure the flooring extends under the door trim.

Bamboo Flooring Pros and Cons

Footstep xi

Finish mark the plank for cutting

Marshal the flooring lengthwise and mark for the notches in the other direction, allowing for the floor to slide under the doorjamb about 3/viii in. Connect the marks with a square and cut out the notch with a jigsaw.

Notched plank particular

The notch in the laminate flooring board has been cut to fit the doorjamb.

Step 12

Glue and install the notched piece

Apply a thin bead of the manufacturer's recommended glue along the edge where the portion of the tongue was removed. Slide the notched piece of flooring into identify and tighten the glued edge by pounding on the special tapping cake.

Repair and Reglue Canvas Vinyl Floors

Step 13

Install the transition strip

Cut a transition molding, in this instance a foursquare nose transition, to fit betwixt the doorstops or jambs. Spread a bead of structure agglutinative only on the area of the concrete flooring that will be in contact with the transition piece. Set the transition in place and weight information technology downwards overnight. You tin't utilize the same tilt and snap installation technique where the flooring fits under doorjambs. You take to slide the floor together instead. Photos 9 - 12 show how. If the opening requires a transition molding, cut the flooring brusque to exit space for it (Photograph xiii).

How to Purchase Wood Floor

Stride 14

Encompass gaps with base trim

Reinstall the shoe molding

Consummate the floor project past trimming off the protruding underlayment with a utility pocketknife and installing shoe molding. Predrill one/xvi-in. holes through the shoe. And so nail the shoe molding to the baseboard with 4d finish nails. Prepare and fill the nails. Exercise non nail downwards into the flooring. Complete the floor by cutting the last row to the right width to fit against the wall. Make sure to leave the required expansion space. Finally, reinstall the baseboards if you removed them, or install new quarter-round or shoe molding to cover the expansion space (Photo 14). Next, make sure you know how to clean laminate floors to keep them looking similar new.

How to Install Cork Tile Flooring

Source: https://www.familyhandyman.com/project/how-to-install-a-snap-together-wood-floor/

Posted by: petersonafess1946.blogspot.com

0 Response to "What Do You Clean A Snaplock Floor With"

Post a Comment